The development and the subsequent maintenance of infrastructure are equally important. Track inspection techniques and systems play an important role in these processes. There are currently a range of track inspection systems, however automated systems are only accessible for large railway administrators such as Adif or FGC on a large scale. Other administrators with fewer resources base their inspections on a series of manual systems, making it necessary to run several inspections to collect all the data required for analysis.

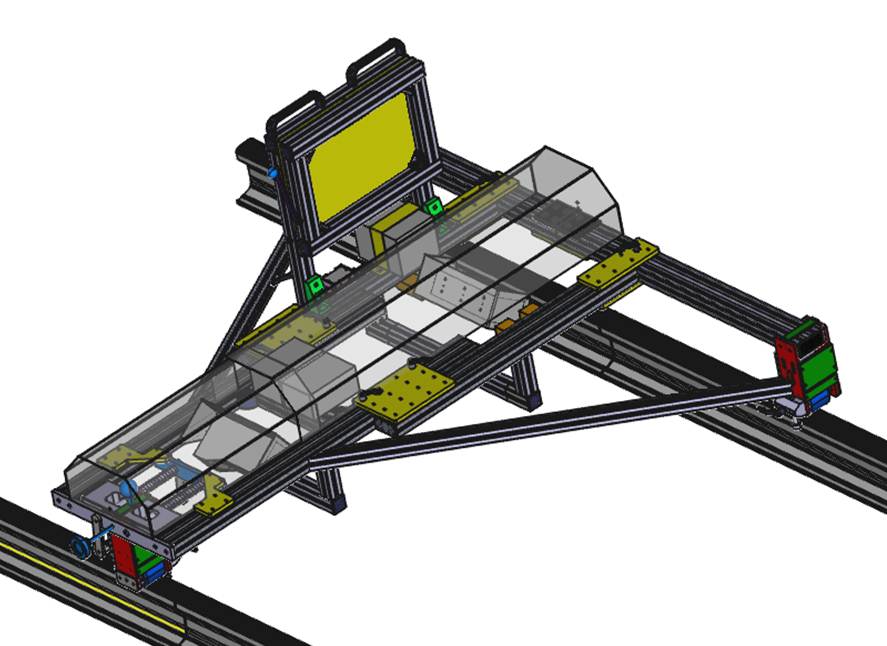

There are many measurement systems for rail inspection on the market, but they all focus on measuring specific characteristics, excluding all others; they either measure geometric parameters, or rail profile, or rail corrugation, etc. With SADA, we have achieved a single system that measures all the parameters characterising rail condition.